Professional Laser Cutting Services

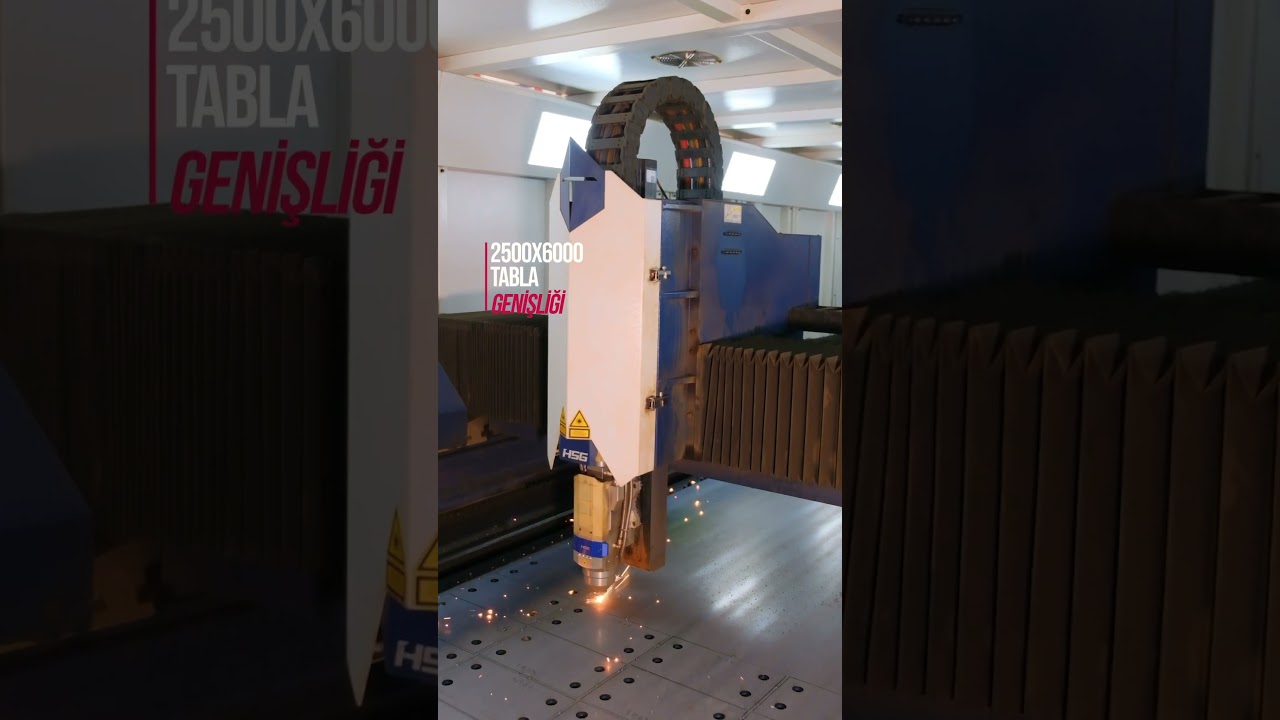

Laser Cutting is a high-tech method using CNC laser cutting machines that ensures precision and efficiency in industrial manufacturing. It can be applied to various materials such as metal, pipes, sheets, and rolled steel. You can request our metal laser cutting machine services from all regions, especially from Ankara (Ostim, İvedik, Siteler, Sincan, Kahramankazan).

With the same enthusiasm as the first day we started trading...

YAKUP YILMAZ BORU PROFİL A.Ş. offers laser cutting CNC services tailored to the job type and material, combining industry experience with "quality, service, and sustainability" principles. We provide timely and cost-effective metal laser cutting and subcontract laser cutting services.

With the same enthusiasm as the first day we started trading...

Our Quality CertificatesWhat is Laser Cutting?

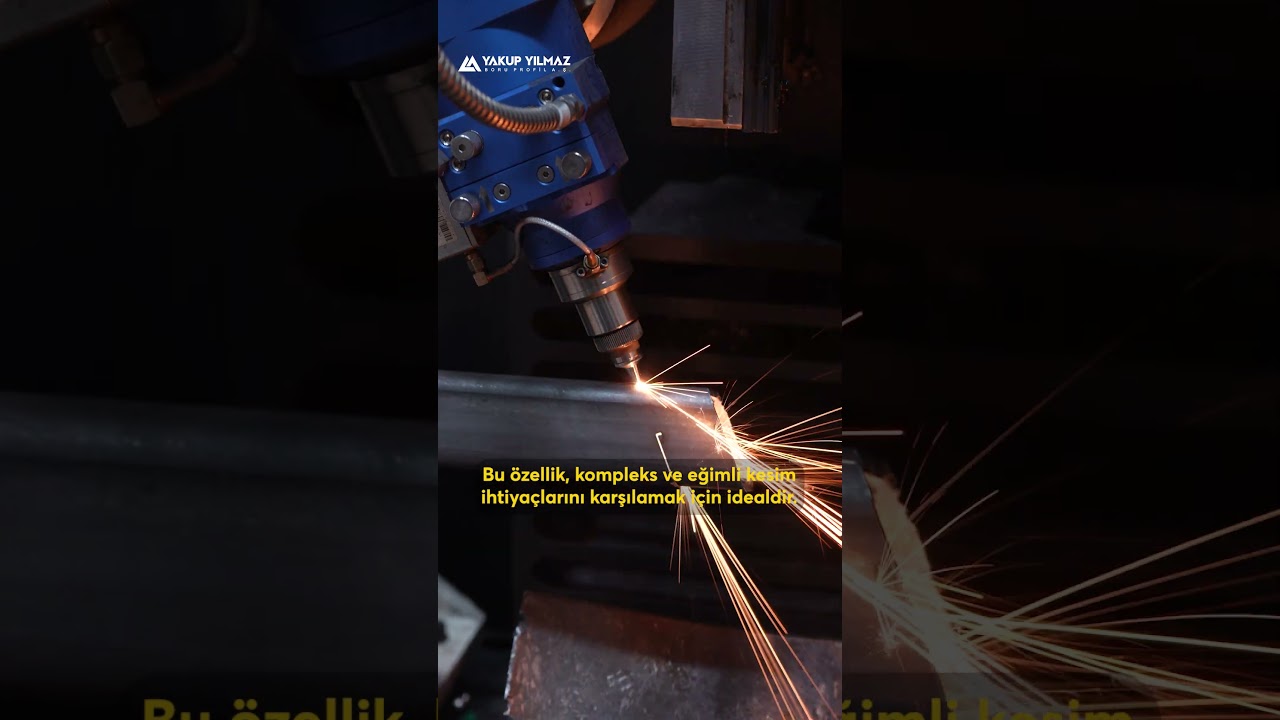

Laser cutting is a modern technique that uses a focused laser beam to cut materials with high precision. The laser melts, evaporates, or burns the material by focusing light on its surface.

How is Laser Cutting Done?

The process involves using CNC (Computer Numerical Control) controlled lasers. The design to be cut is first created digitally and transferred to the laser machine. The machine follows this design, focusing the laser beam accordingly. Power and speed are adjusted based on the material type and thickness. The result is a precise cut without mechanical wear.

Applications & Advantages of Laser Cutting

Laser cutting is used in metalworking, automotive, aerospace, furniture, and decoration industries.

Laser cutting machines can create decorative objects, industrial parts, signage, fashion accessories, models, and prototypes. They are also used for personalized gifts and art pieces.

Why Use Laser Cutting?

Laser cutting is preferred for applications that require high precision and speed. It provides minimal material waste and can easily handle complex patterns. Moreover, there is no mechanical contact with the material, eliminating wear and deformation risks.

What are the advantages of laser cutting services?

- Eliminates tooling costs for part manufacturing

- Fast and economical solutions for prototyping

- Rapid processing of various cutting tasks

- High-speed cutting without material contact

- No heat-induced changes on the material

- Minimal waste compared to pressing

- Ability to engrave and mark on sheet surfaces

- Marking of bending lines

- Ability to cut any graphics, text, or images on sheets

- Particularly useful for the advertising sector with speed, technology, and flexibility

- Burr-free cutting

- Suitable for mass and flexible production

Frequently Asked Questions

What can laser cutting cut?

Laser cutting can handle materials like steel, aluminum, stainless steel, sheet metal, pipes, profiles, and NPU materials.

How thick can laser cutting cut?

Depending on the material, laser cutting can cut from 0.1 mm up to 35 mm. In our facility, we cut up to 35 mm for black steel sheets, 35 mm for stainless steel, and 20 mm for aluminum. For pipes, we cut up to 270 mm in diameter.